Industrial Hoses With End Fittings

1200 INR/Piece

Product Details:

- Shape Round

- Medium Water, Oil, Air, Chemicals

- Cover Abrasion and Weather Resistant Synthetic Rubber

- Reinforcement High Tensile Synthetic Textile with Steel Wire Helix

- Connection Type Flanged, Threaded, or Quick Coupler End Fittings

- Hardness 655 Shore A

- Material Nitrile Rubber, EPDM, Neoprene, PVC, or Customized

- Click to View more

X

Industrial Hoses With End Fittings Price And Quantity

- 1200 INR/Piece

- 10 , , Piece

- Industrial fluid transfer, suction and discharge

- As per selected hose material

- IS 444, IS 3549, BS 3395, EN 1761

- Black, Red, Blue or as required

- Up to 60 meters or customized

- Yes

- Excellent

- Yes

- Carbon Steel, Stainless Steel, Brass

- 3 times working pressure

Industrial Hoses With End Fittings Product Specifications

- Water, Oil, Air, Chemicals

- Abrasion and Weather Resistant Synthetic Rubber

- Up to 20 Bar

- Round

- Varies as per ID and construction

- -40C to +120C

- 655 Shore A

- Nitrile Rubber, EPDM, Neoprene, PVC, or Customized

- 25 mm to 150 mm

- Flanged, Threaded, or Quick Coupler End Fittings

- High Tensile Synthetic Textile with Steel Wire Helix

- Industrial fluid transfer, suction and discharge

- As per selected hose material

- IS 444, IS 3549, BS 3395, EN 1761

- Black, Red, Blue or as required

- Up to 60 meters or customized

- Yes

- Excellent

- Yes

- Carbon Steel, Stainless Steel, Brass

- 3 times working pressure

Industrial Hoses With End Fittings Trade Information

- Paypal, Cash in Advance (CID), Cheque, Cash Advance (CA)

- 100-150 , , Piece Per Day

- 2-3 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

Product Description

The provided Industrial Hoses With End Fittings are designed with tough tempered steel material that is twisted in a hose form. These are outlined with end fittings that are simple to attach onto varied pipeline systems. They are twisted to enable the customers to attach them into varied complex systems for effective operations and handling.

Versatile Industrial Applications

Designed to handle water, oil, air, and chemicals, our hoses are ideal for general fluid transfer, industrial suction, and discharge operations. Excellent flexibility and robust construction make them suitable for a wide variety of sectors including manufacturing, construction, and chemical processing.

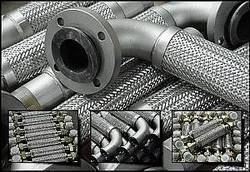

Superior Materials and Construction

Our hoses are crafted from high-quality materials such as nitrile rubber, EPDM, neoprene, or PVC, with a reinforcing steel wire helix and abrasion-resistant synthetic rubber cover. This ensures longevity, resistance to ozone and UV, and dependable performance in harsh conditions.

Custom Options for Every Requirement

We offer hoses in an array of colors, end fittings, lengths, and diameters to fit your specific application. With the ability to withstand temperatures from -40C to +120C and customizable assembly, our products deliver tailored solutions for your industrial challenges.

FAQs of Industrial Hoses With End Fittings:

Q: How can I customize the length and color of industrial hoses?

A: You can request hoses up to 60 meters in length or specify custom measurements to fit your applications needs. Color options include black, red, blue, or any preference you may have, ensuring alignment with your project specifications.Q: What industries benefit most from these hoses with end fittings?

A: Industries such as manufacturing, chemical processing, construction, and water treatment benefit greatly due to the hoses robust construction, excellent flexibility, and capability to handle various media like water, oil, air, and chemicals.Q: When should I select carbon steel, stainless steel, or brass for end fittings?

A: The choice depends on the fluid being conveyed and environmental conditions. Stainless steel is ideal for corrosive environments and chemical transfer, while carbon steel suits general purpose use. Brass is preferred for non-corrosive, water-based applications.Q: Where are these hoses typically installed and operated?

A: These hoses are commonly used in industrial facilities, pump stations, factories, chemical plants, and construction sites, wherever reliable suction and discharge or fluid transfer is essential.Q: What is the recommended process for selecting the right hose for my application?

A: Consider the working fluid, pressure, temperature, required flexibility, and environmental conditions. Also, assess compliance with standards such as IS 444 or EN 1761. Consulting with our technical team can help identify the optimal hose configuration for your specific need.Q: How do the hoses offer benefits in terms of safety and durability?

A: With a burst pressure rating three times the working pressure, compliance with international standards, and resistance to abrasion, ozone, and UV, these hoses ensure high safety margins and a prolonged service life even in challenging operating conditions.Q: Can these hoses be used in both indoor and outdoor environments?

A: Yes, engineered with a weather-resistant cover and resistance to UV rays and ozone, the hoses are well-suited for both indoor installations and challenging outdoor environments, maintaining durability and performance over time.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Hoses' category

|

SURYA ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |